Research Interests

Biosurfactants for various applications

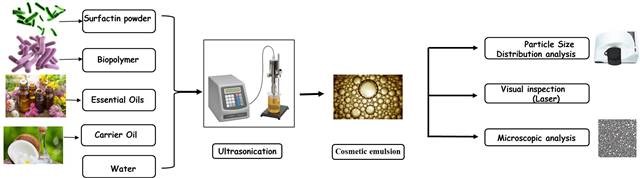

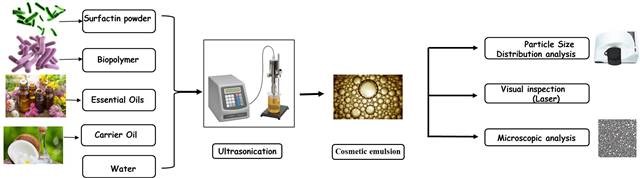

My primary research area centers around microbial-derived surfactants, primarily sourced from Bacillus sp. These biosurfactants exhibit remarkable functional properties and are gaining increasing attention for their diverse applications in agriculture, cosmetics, food, healthcare, and the oil recovery sectors.

Throughout my research journey, spanning both my Ph.D. and postdoctoral work, my focus has primarily revolved around intensifying the bioprocess for simultaneous production and purification of these surface-active biomolecules. While the bulk of my efforts has been directed towards process optimization, I have also delved into their practical applications to some extent.As a part of my Ph.D. work, I successfully developed a straightforward method for synthesizing highly stable Ag-nanoparticles colloidal suspension, capped with lipopeptides. This innovative approach exhibited remarkable antimicrobial properties. Presently, my research has evolved to explore additional dimensions of biosurfactant applications, including their incorporation into cosmetic formulations and their potential in antimicrobial solutions and oil recovery processes.

Hydrolytic enzymes for the production of reducing sugars

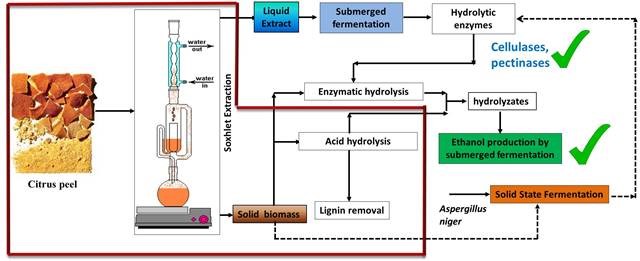

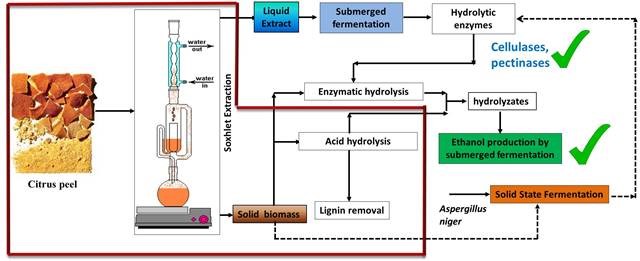

In the coming years, the widespread adoption of ethanol-blended gasoline is poised to become a global imperative, driven by the urgent need to mitigate greenhouse gas emissions. Historically, bioethanol production has predominantly relied on starch-based feedstocks like corn, sugarcane, potatoes, and cassava. However, the utilization of these resources has sparked an enduring debate pitting food against fuel.

Fortunately, advancements in biomass hydrolysis techniques, particularly thermochemical methods, have rendered bioethanol production from lignocellulosic biomass a promising and sustainable alternative. More recently, attention has shifted towards cleaner, energy-efficient approaches, specifically enzymatic processes designed for the efficient hydrolysis of complex cellulosic substrates.

The forefront of research now predominantly centers on lignocellulosic biomass sourced from wood, grasses, and agricultural residues. Our ongoing research initiatives are directed towards an innovative avenue: utilizing fruit waste from fruit processing industries as a feedstock for bioethanol production. Simultaneously, we are exploring the transformation of soluble sugars extracted from fruit waste into valuable biopolymers. These endeavors align with our commitment to sustainable and eco-friendly solutions in the realm of biofuels and biomaterials.

Cashew research

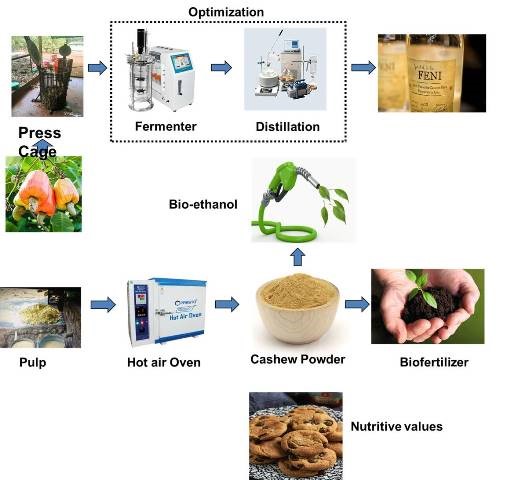

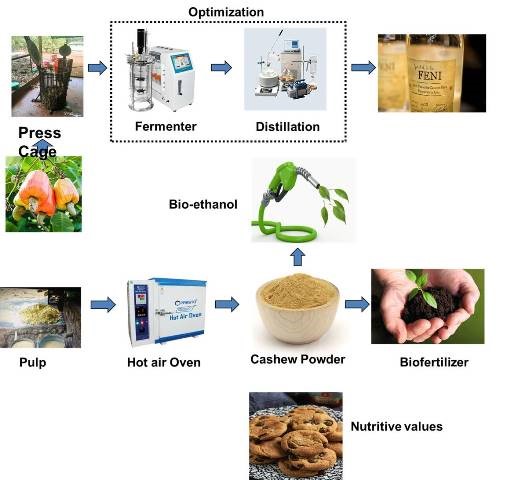

The art of fermenting cashew apple juice persists, yet there remains a notable absence of systematic scientific insights into the entire Feni production process. Such insights encompass critical facets like process consistency, the aromatic attributes, and the chemical quality parameters of the resulting distillate. Elevating our understanding of these elements holds the potential to significantly enhance the commercial value of Feni as a product.

As the demand for Feni in foreign markets experiences a noticeable uptick, some Feni producers have expressed a keen interest in elevating the quality and reputation of their offerings. In light of this growing need for improvement, particularly among small-scale cashew producers who operate clustered production units, and recognizing the dearth of comprehensive literature on Feni production, our research endeavors aim to unravel the intricate interplay of these aforementioned factors and their collective impact on the overall quality of Feni. Through our investigations, we seek to contribute valuable insights to this unique and culturally significant industry.

Biopolymers for various applications

We mainly focus on thermophilic bacteria to produce thermo-tolerant biopolymers which have imminent potential for applications in food, cosmetics, fly-ash disposal, enhanced oil recovery etc. We exploring the feasibility of using various agro-industrial wastes as substrates for the production of bio-polymer through solar powered bioreactors.

Positions available for PhD/N-PDF:

Interested students with Master's in Chemical Engineering/Biotechnology/ Biochemical Engineering and with a valid GATE score can contact me. Email: vivekr@goa.bits-pilani.ac.in

*There will be a call for PhD under Institute research fellowship (BITS Pilani) in the month of Nov/Dec 2019. As per this scheme, the selected student will receive a monthly stipend from the Institute for a period of 5 years. (Rs. 37000 for the first 2 years, which would be enhanced to Rs. 40000/42000 upon satisfactory performance)

An Institute of Eminence

An Institute of Eminence