In recent years, the exploration of flexible and wearable electronics has gained significant momentum. Integrating advanced materials into everyday items, such as paper and fabric, opens up possibilities for developing efficient and versatile devices. One innovative advancement is developing Shellac-mediated one-step laser-induced reduced graphene oxide (rGO) films.

This groundbreaking research was conducted by Pavar Saikumar (PhD Scholar) under the supervision of Prof. Sanket Goel, Dean R&I, Birla Institute of Technology and Science (BITS) Pilani, Hyderabad Campus, and Industry Partner, Chandrani Pramanik, Tata Steel Limited, Jharkhand. This study has showcased the exceptional performance of patterning possible one-step conductive rGO traces in 4 significant applications. The study highlights the use of these rGO films in flexible fuel cells, supercapacitors, flexible electronics and electrocardiography applications, marking a significant leap forward in the field of flexible electronics. The study investigates using a natural biodegradable polymer, shellac, to enhance the properties of laser-induced reduced graphene oxide (rGO) on paper and fabric substrates. The method improved rGO with low electrical sheet resistances and potential applications in biofuel cells, supercapacitors, and electrocardiography. Structural, morphological, and elemental analysis confirmed successful rGO development on both substrates. XPS analysis revealed chemical bonding of rGO, and optical characterizations showed electronic transitions in the material.

Key Insights

- Shellac can enhance the properties of rGO on paper and fabric substrates.

- The method improves rGO with low electrical sheet resistances (as low as 2.3 Ω Sq.−1) and minimal rGO sheet layers (~ 11).

- Potential applications of shellac-mediated rGO include biofuel cells, supercapacitors, and electrocardiography.

- Thorough material characterization (structural, morphological, Raman spectra and elemental analysis reveal the successful rGO development on paper and fabric.

- XPS analysis reveals the elemental information of rGO and UV-Vis (optical characterizations) shows electronic transitions in the material.

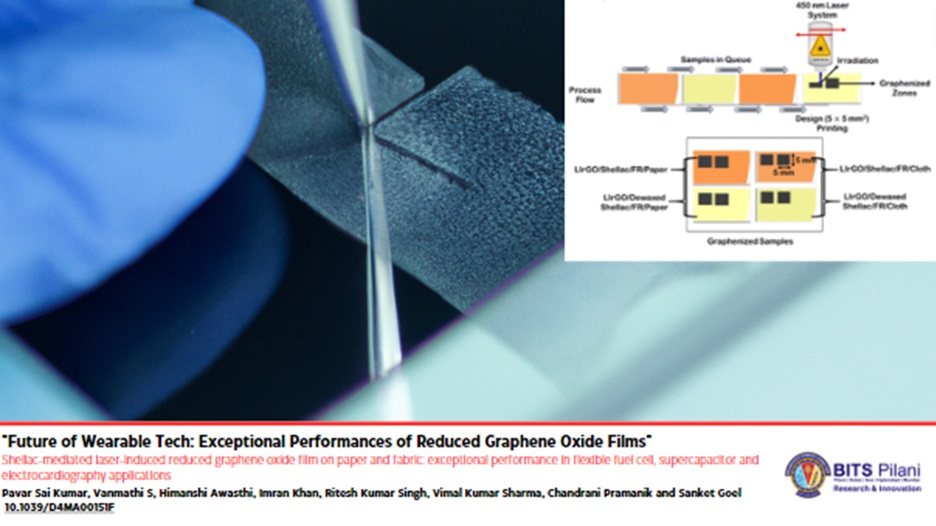

The development of optimized approaches, particularly those that use natural sources, has been hastened due to the varied features of graphene and auxiliary materials in various fields. In this study, natural shellac (biopolymer) (C25H51COOH), which possesses long carbon chains by its very nature, is utilized as a possible resource to enhance the physiochemical features of laser-induced reduced graphene oxide (rGO). A versatile blue diode laser with a wavelength of 450 nm was utilized to manufacture biopolymer-assisted rGO on environmentally acceptable flexible paper and textile samples. Using this approach, an enhanced rGO was produced, exhibiting electrical sheet resistances as low as 2.3 Ω Sq.−1. In addition, comprehensive characterizations demonstrated that the typical number of rGO layers is as low as 11. The potential of rGO helped by shellac was shown through four critical applications. The initial step was the development of a disposable two-electrode enzymatic biofuel cell (EBFC) using paper samples that were helped by biopolymer. This resulted in generating a power density of 66.7 µW/cm2. Second, rGO interdigitated electrode (IDE) supercapacitors were printed on dual-shellac paper types. These supercapacitors demonstrated a maximum areal capacitance of 31.25 mF cm−2 when subjected to a current density of 0.5 mA cm−2. Lastly, the rGO-patterned electrode system placed on biopolymer-assisted paper successfully produced significant conventional electrocardiogram (ECG) signals, notably P, R, T, and QRS complexes.

Furthermore, the signal-to-noise ratio (S/N ratio) significantly rose to 24 %, reaching a level higher than the S/N ratio recorded when utilizing the typical Ag/AgCl electrode system. Additionally, printed electronic circuits were patterned and exhibited on textile samples for applications that could be worn. The enhancement of rGO by exploring natural biopolymers offers tremendous promise for a wide variety of potential applications in the future. As we reflect on the potential impacts of this remarkable research, we anticipate the exciting future of flexible electronics and its transformative possibilities.

An Institute of Eminence

An Institute of Eminence